The clutch and flywheel kit is essential for smooth power transfer in vehicles, preventing performance issues like slippage and erratic gear shifts. Regular checks are vital when upgrading other components. Failure signs include unusual noises, vibrations, reduced acceleration, and gear shifting problems. Troubleshoot by inspecting components, using diagnostic scanners, listening for noises, and checking suspension malfunctions for accurate diagnosis.

Are you experiencing strange noises or performance issues with your vehicle? It might be time to scrutinize your clutch and flywheel kit. This comprehensive guide dives into the intricate world of these essential components, helping you identify common signs of wear and tear. From understanding their functionality to effective testing methods, gain valuable insights for maintaining optimal vehicle health. Learn how to recognize faulty parts early on and ensure a smooth ride ahead.

- Understanding Clutch and Flywheel Kit Functionality

- Common Signs of Faulty Clutch Components

- Testing and Diagnosing Flywheel Kit Issues Effectively

Understanding Clutch and Flywheel Kit Functionality

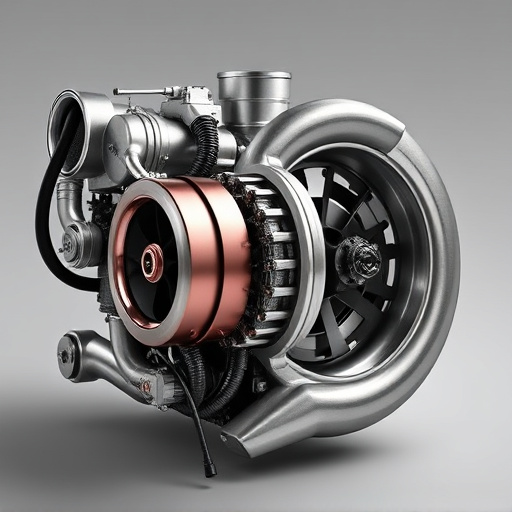

The clutch and flywheel kit is a critical component in any vehicle’s transmission system, responsible for smooth gear changes and power transfer from the engine to the wheels. The clutch engages and disengages the engine to the gearbox, allowing drivers to shift gears effortlessly. Meanwhile, the flywheel acts as a rotating mass that stores energy and helps absorb torque variations, ensuring a seamless driving experience.

These kits work in harmony to manage the vehicle’s power output. When driving, the clutch disc, pressed by the clutch pedal, separates the engine from the gearbox, enabling gear changes. The flywheel, connected to the clutch hub, provides the necessary rotational force and helps maintain consistent power delivery. Maintaining the integrity of these parts is crucial; any faults can lead to performance issues, such as slippage or erratic gear changes, impacting driving dynamics and potentially causing more severe mechanical problems in the transmission system. Regular checks, especially when considering upgrades like air filter kits, performance brakes, or performance exhausts, are essential to identify potential issues early on.

Common Signs of Faulty Clutch Components

The clutch and flywheel kit are essential components that facilitate smooth power transfer in a vehicle’s transmission system. When these parts start to fail, it often manifests through several noticeable signs. One of the earliest indications is unusual noise coming from the engine compartment, such as grinding or clicking sounds during clutch engagement. This could be an indicator of worn-out clutch discs or pressured plates that no longer grasp effectively.

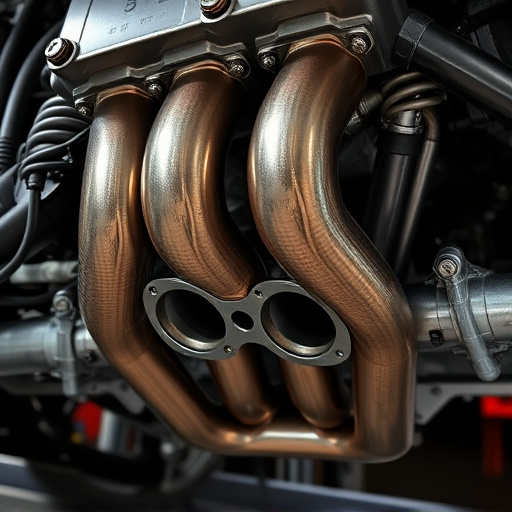

Additionally, a faulty flywheel may cause vibrations or shudders while driving, particularly at lower speeds. The vehicle’s performance will also take a hit, showing signs of reduced acceleration and power delivery. If you notice sluggishness when shifting gears or difficulty in engaging the clutch, it could point towards issues with these critical transmission parts. Other symptoms include unusual exhaust noise from compromised exhaust systems or changes in engine behavior due to malfunctioning suspension components and intake systems.

Testing and Diagnosing Flywheel Kit Issues Effectively

When diagnosing flywheel kit issues, a systematic approach is key. Start by checking for physical damage or wear to the clutch and flywheel parts. Inspect the pressure plate, release bearing, and clutch disc for any cracks, pitting, or excessive wear. A damaged clutch assembly can cause a vehicle’s clutch to slip or engage erratically. Next, assess the condition of the flywheel itself. Look for signs of corrosion, warping, or cracks, as these can impact the engine’s ability to transfer power smoothly. A worn or damaged flywheel may also lead to unusual noise and vibration during acceleration.

Effective testing involves more than just visual inspections. Connect a diagnostic scanner to the vehicle’s computer system to retrieve error codes related to the clutch and transmission. These codes can pinpoint specific components that may be failing, such as issues with the clutch slave cylinder or hydraulic lines. Additionally, listen for unusual noises coming from the engine bay during acceleration or deceleration, which could indicate problems with misaligned muffler tips or damaged air intake systems. Even suspension components might play a role, so rule out any suspension-related malfunctions that could indirectly affect clutch performance.

Identifying faulty clutch and flywheel kit parts is crucial for maintaining optimal vehicle performance. By understanding the functionality of these components, recognizing common signs of malfunction, and employing effective testing methods, you can effectively diagnose and address issues early on. Regular maintenance and timely repairs not only enhance your driving experience but also contribute to the longevity of your vehicle’s transmission system.