Selecting Top Clutch and Flywheel Kit Brands

A high-quality clutch and flywheel kit from reputable brands is crucial for efficient power transfer…….

Welcome to an in-depth exploration of the crucial automotive component known as the clutch and flywheel kit. This article aims to decipher the intricacies of this essential system, shedding light on its global impact, technological advancements, economic implications, and future prospects. By delving into these aspects, we will equip readers with a comprehensive understanding of why clutch and flywheel kits are not just mechanical parts but pivotal elements in the world of transportation.

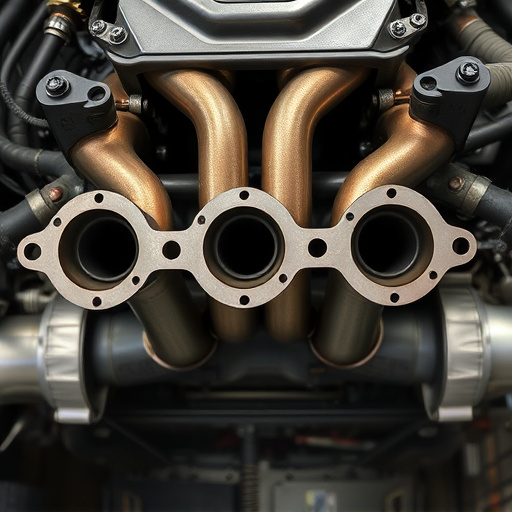

Definition: A clutch and flywheel kit is a vital mechanical assembly found in vehicles, primarily in manual transmission cars and motorcycles. It facilitates the efficient transfer of power from the engine to the transmission system, enabling smooth gear changes and controlled acceleration.

Components: The kit comprises several critical parts:

Clutch: This is a device that disengages the engine from the transmission, allowing drivers to change gears. It consists of a pressure plate, clutch disc, and release bearing. When engaged, the clutch connects the engine to the flywheel.

Flywheel: A heavy disc-like component connected to the clutch. Its primary function is to store rotational energy from the engine and smoothen power delivery. Flywheels help reduce vibration and provide a consistent torque output.

Pressure Plate: The metal plate that presses against the clutch disc, engaging the clutch. It is typically mounted on the transmission side of the clutch assembly.

Clutch Master Cylinder: Part of the hydraulic system, it generates pressure to engage the clutch. Driven by the driver’s pedal input through the clutch pedal, it communicates with the slave cylinder.

Slave Cylinder: Located close to the clutch master cylinder, it receives hydraulic pressure and translates it into mechanical force to actuate the release bearing, disengaging the clutch.

Historical Context: The concept of a clutch system dates back to the late 19th century when automobiles were in their infancy. Early vehicles relied on manual transmission systems, requiring drivers to physically engage and disengage gears using a lever and clutch pedal. Over time, the design evolved to include hydraulic and mechanical assistance, making gear changes smoother and more efficient.

Significance: Clutch and flywheel kits play a pivotal role in vehicle performance and drivability. They enable drivers to control engine power, ensuring optimal acceleration, smooth gear shifts, and improved overall driving experience. Moreover, they contribute to fuel efficiency and engine longevity by facilitating more precise power management.

The clutch and flywheel kit’s influence extends far beyond borders, with varying regional trends shaping its development and adoption:

North America: The United States and Canada have historically been significant markets for advanced clutch technology, driven by a preference for high-performance vehicles and stringent emission standards. Companies like Ford, General Motors, and Tesla have played pivotal roles in refining clutch systems for electric and hybrid vehicles.

Europe: Known for its stringent safety and environmental regulations, Europe has driven innovation in clutch technology. German automotive giants like Volkswagen and BMW have been at the forefront of developing efficient, lightweight clutch kits to meet fuel economy goals.

Asia Pacific: This region, particularly countries like Japan and South Korea, is witnessing a boom in electric vehicle (EV) adoption. As a result, there is a growing demand for compact, high-performance clutch systems tailored for EV transmissions.

Emerging Markets: Countries in Southeast Asia and South America are experiencing rapid motorization, leading to increased demand for affordable yet reliable clutch kits. Local automotive manufacturers are partnering with global suppliers to meet these needs.

Market Dynamics: The global clutch and flywheel kit market is characterized by intense competition, with numerous players offering a range of products catering to different vehicle segments. According to a 2022 report by Market Research Future (MRFR), the market is projected to reach USD 16.5 billion by 2027, growing at a CAGR of 6.7% during the forecast period.

Investment Patterns: Major automotive manufacturers invest heavily in clutch technology research and development (R&D) to create more efficient, lightweight, and durable systems. These investments drive innovation, improve vehicle performance, and reduce overall production costs.

Economic Impact: The economic significance of clutch and flywheel kits extends beyond the automotive sector. They contribute to:

The field of clutch technology has witnessed several groundbreaking advancements in recent years:

| Advancement | Description | Impact | Future Potential |

|---|---|---|---|

| Dry Clutch Systems | Traditional wet clutches use hydraulic fluid, but dry clutches employ a spring-loaded mechanism. They offer faster engagement, reduced slip, and improved durability. | Dry clutches enhance vehicle performance and reduce fluid maintenance requirements. | Expected to gain traction in high-performance vehicles and racing applications. |

| Electronically Controlled Clutches (ECC) | ECCs utilize electronic sensors and actuators to precisely control clutch engagement. This technology improves drivability and reduces wear. | Enhances driver comfort and fuel efficiency, with potential for integration into advanced driver-assistance systems (ADAS). | Integration with autonomous driving technologies could lead to more sophisticated gear change strategies. |

| Lightweight Flywheels | Manufactured from lightweight materials like carbon fiber, these flywheels reduce rotational inertia, improving engine responsiveness and fuel economy. | Significantly enhances vehicle dynamics and reduces overall weight, contributing to improved performance and efficiency. | Essential for the growing demand for lightweight, high-performance vehicles. |

| Hybrid Clutch Systems | Combines elements of wet and dry clutches, offering advantages from both technologies. They provide smooth gear changes and efficient power transmission. | Ideal for electric and hybrid vehicles, enhancing overall system performance and reducing complexity. | Likely to become more prevalent as the EV market expands. |

| Smart Clutch Systems | Incorporates sensors and actuators to adapt clutch behavior based on driving conditions, engine load, and vehicle speed. | Optimizes drivability and fuel economy by automating gear changes, especially in stop-and-go traffic. | Could lead to more autonomous driving capabilities. |

The development and use of clutch and flywheel kits are subject to various global policies and regulations:

Emission Standards: Many countries have stringent emission norms that influence clutch design, especially in vehicles with internal combustion engines. Manufacturers must meet these standards while ensuring optimal power delivery.

Safety Regulations: Clutch systems must adhere to safety standards regarding driver control and gear change mechanisms. Testing and certification processes ensure their reliability and performance.

Environmental Compliance: The European Union’s (EU) Eco-Design Directive requires manufacturers to consider the environmental impact of clutch kits, promoting the use of sustainable materials and efficient designs.

Product Safety and Liability: Governments enforce regulations to protect consumers from defective products. Manufacturers must ensure clutch kits meet quality and safety standards to avoid legal repercussions.

Despite its numerous advantages, the clutch and flywheel kit faces several challenges:

Wear and Tear: Continuous use leads to wear on clutch components, especially in vehicles subjected to severe driving conditions or frequent gear changes. Regular maintenance is crucial to mitigate this issue.

Complexity: Modern clutch systems, particularly those with electronic controls, are highly complex. This complexity can make repairs more challenging and expensive, requiring specialized knowledge.

Noise and Vibration: In some cases, clutch engagement can produce noticeable noise and vibration, impacting the driving experience. Designers work to address these issues through improved materials and precision engineering.

Solutions and Strategies:

Case Study 1: Tesla Model 3 and Advanced Clutch Technology

Tesla, the electric vehicle pioneer, has incorporated cutting-edge clutch systems in its Model 3 sedan. Their unique dual-motor all-wheel-drive (AWD) configuration uses a sophisticated clutch assembly to distribute power between motors for optimal traction and performance. This system enables rapid acceleration and efficient energy transfer, setting a new benchmark for electric vehicle dynamics.

Case Study 2: BMW’s Lightweight Clutch Kit in the X5 SUV

BMW equipped its X5 SUV with a lightweight flywheel and clutch kit as part of a broader effort to enhance fuel efficiency and performance. The kit reduced the vehicle’s overall weight, resulting in improved handling and better fuel economy, especially during urban driving conditions. This case highlights the impact of material choices and design innovations on vehicle dynamics.

Case Study 3: Ford F-150 and Hybrid Clutch Systems

Ford’s popular F-150 pickup truck features a hybrid clutch system, offering both efficiency and power. This technology allows for smoother gear changes in electric-only mode while providing robust torque when the engine is used. The F-150’s versatile clutch system caters to various driving scenarios, from urban commuting to heavy towing.

The future of clutch and flywheel kits is filled with promising trends and growth areas:

Electric Vehicle Integration: As the electric vehicle market continues to grow, clutch technology will play a pivotal role in developing efficient, compact, and high-performance systems for EVs.

Autonomous Driving: Advanced driver-assistance systems (ADAS) and autonomous driving technologies will rely on sophisticated clutch controls for smoother gear changes and improved vehicle dynamics during automated driving modes.

Sustainable Materials: The automotive industry’s focus on sustainability will drive the adoption of lightweight, eco-friendly materials for flywheels and clutches, reducing environmental impact.

Digitalization and Connectivity: Integration with digital systems and connectivity will enable clutch kits to receive over-the-air updates, improving performance and facilitating remote monitoring and diagnostics.

In conclusion, clutch and flywheel kits are not merely mechanical components but dynamic elements shaping the future of transportation. Their global impact is evident in improved vehicle performance, efficiency, and sustainability. As technology advances, these kits will continue to evolve, addressing challenges while opening new avenues for innovation.

The ongoing transition towards electric and autonomous vehicles underscores the importance of clutch technology research and development. By embracing emerging trends and adopting sustainable practices, manufacturers can ensure that clutch and flywheel kits remain at the forefront of automotive progress.

Q: How often should I replace my clutch kit?

A: The frequency depends on various factors, including driving habits, vehicle use, and maintenance history. Generally, a complete clutch kit replacement is recommended every 50,000 to 100,000 kilometers or at signs of wear, such as unusual noise or performance issues.

Q: Can I drive with a worn-out clutch?

A: Driving with a severely worn clutch can lead to reduced control and increased strain on other components. It’s advisable to have it inspected and serviced promptly to avoid potential safety hazards and further damage.

Q: What are the environmental benefits of advanced clutch technology?

A: Improved efficiency and lighter materials contribute to lower fuel consumption and reduced greenhouse gas emissions, aligning with global efforts to combat climate change.

Q: How do electronically controlled clutches (ECCs) enhance vehicle performance?

A: ECCs provide precise control over clutch engagement, allowing for faster gear changes and improved engine responsiveness. This technology reduces slip, enhancing overall vehicle dynamics and drivability.

Q: Are there any safety concerns related to clutch systems?

A: Properly designed and maintained clutch systems are safe. However, faulty or poorly serviced clutches may pose risks. Regular maintenance and adherence to manufacturer recommendations mitigate these concerns.

A high-quality clutch and flywheel kit from reputable brands is crucial for efficient power transfer…….

Upgrading to a clutch and flywheel kit boosts vehicle performance and handling. Choose high-quality…….

A clutch and flywheel kit is vital for smooth power transfer in vehicles, comprising disc, pressure…….

Your driving style guides selection of clutch and flywheel kit, crucial for performance. Casual driv…….

Before changing a clutch and flywheel kit DIY, gather essential tools like jack stands, floor jacks,…….

The clutch and flywheel kit is essential for smooth gear shifting and driver control in a vehicle�…….

Before replacing a clutch and flywheel kit, assess vehicle performance, prepare tools and parts, fol…….

The clutch and flywheel kit is a transmission system cornerstone, enabling power transfer from engin…….

A clutch and flywheel kit is essential for smooth gear changes and power delivery in vehicles. Degra…….

The clutch and flywheel kit is essential for smooth power transfer in vehicles, preventing performan…….