The clutch and flywheel kit is essential for smooth gear shifting and driver control in a vehicle's transmission system. Regular maintenance prevents issues and optimizes performance, with wear and tear impacting operation. Failure signs include grinding noises, increased vibration, and excessive heat near the clutch housing, leading to poor performance and safety risks. Troubleshooting involves inspecting clutch assembly, flywheel, hydraulic system, and monitoring exhaust tips for anomalies. Timely replacement of wear items and regular maintenance are key to preventing clutch and flywheel kit problems.

Diagnosing issues with your vehicle’s clutch and flywheel kit is crucial for maintaining optimal performance. This guide breaks down the basics of clutch and flywheel function, common failure symptoms, and a step-by-step troubleshooting process for DIY repair enthusiasts. By understanding these components and their interactions, you’ll be equipped to identify problems early on, ensuring smoother drives and saving potential repair costs associated with clutch and flywheel kit failures.

- Understanding Clutch and Flywheel Kit Basics

- Common Symptoms of Clutch and Flywheel Failure

- Troubleshooting and Diagnostic Steps for Repair

Understanding Clutch and Flywheel Kit Basics

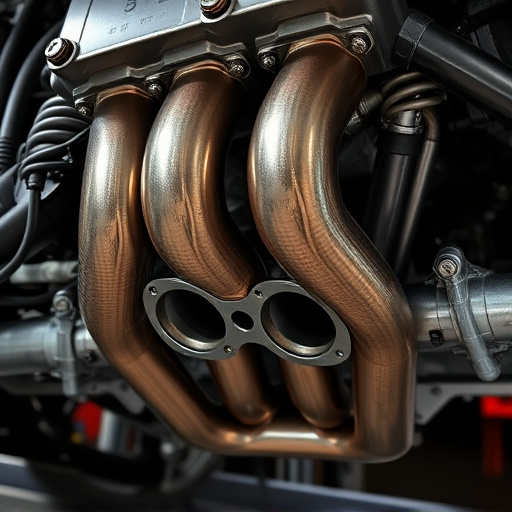

The clutch and flywheel kit is a fundamental component of any vehicle’s transmission system, enabling smooth shifting and driver control. At its core, the clutch works by disengaging the engine from the drivetrain, allowing drivers to change gears effortlessly. This is achieved through a combination of friction materials and springs within the clutch assembly. The flywheel, on the other hand, serves as the rotating mass that stores energy from the engine, contributing to improved performance and efficiency. Together, these components form a critical partnership, ensuring seamless power transfer from the engine to the transmission.

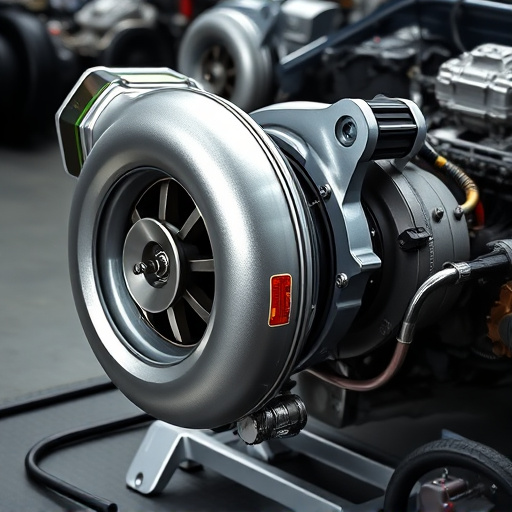

When troubleshooting issues with a clutch and flywheel kit, it’s essential to consider various factors. Over time, wear and tear can affect the friction materials, leading to reduced clutch engagement. Additionally, damage or imbalances in the flywheel can cause vibrations and performance problems. Upgrades such as high-performance exhaust systems, cold air intakes, and exhaust tips may also impact the clutch and flywheel’s operation, especially if not properly specified for the vehicle. Regular maintenance and timely repairs are crucial to maintaining optimal performance, ensuring a smooth driving experience, and preventing more serious transmission issues down the line.

Common Symptoms of Clutch and Flywheel Failure

When a clutch and flywheel kit starts to fail, it can manifest through various symptoms that signal a need for immediate attention. One of the most common indicators is a grinding or chirping noise during gear changes, which suggests that the clutch disc has worn out and is no longer providing smooth engagement. This issue can lead to difficulty in shifting gears and may even cause the vehicle to stall.

Another sign of trouble is increased vibration while driving, especially at lower speeds. If you notice your steering wheel shaking or the vehicle feeling unpredictable, it could be a red flag. Moreover, excessive heat build-up near the clutch housing is a serious concern as it can lead to reduced lifespan and potential damage to surrounding components. In terms of vehicle performance, a failing clutch and flywheel kit may result in delayed acceleration and a loss of power, particularly when trying to pass other vehicles on the road. These symptoms highlight the importance of regular maintenance and prompt replacement of worn-out parts to ensure optimal vehicle performance and safety.

Troubleshooting and Diagnostic Steps for Repair

When troubleshooting issues with a clutch and flywheel kit, start by observing any unusual noises or vibrations during engagement. These could indicate worn or damaged components within the clutch assembly. Check for signs of wear on the clutch disc, pressure plate, and flywheel, as these are common areas of failure. A visual inspection should also reveal any damage to the input shaft or transmission seals.

Next, verify the condition of the flywheel itself. A warped or damaged flywheel can cause improper alignment and lead to early wear on the clutch components. Ensure that the flywheel is clean and free from debris. Further diagnostics may involve testing the pressure of your clutch master cylinder and checking for leaks in the hydraulic system. Regular maintenance, including timely replacement of wear items like the air filter kits and cold air intakes, can help prevent many of these issues. Keep an eye on any unusual exhaust tips or odors coming from the engine bay, as they could also be indicative of problems with the clutch and flywheel kit.

Diagnosing issues with a clutch and flywheel kit is crucial for maintaining optimal vehicle performance. By understanding basic components, recognizing common symptoms like slippage or sudden engagement problems, and following structured troubleshooting steps, you can effectively identify and address problems. Regular maintenance checks and prompt repairs are key to ensuring your vehicle’s safety and efficiency, preserving the integrity of your clutch and flywheel kit for many driving years to come.